Top Class T-shirt Printing Methods for Best Results – 4 Different Ways

Printing the shirts is always exciting and sometimes a bit costly. Finding the method which is economical and can give you state-of-the-art results with your printing journey is not accessible if you are just starting. Hence, you need to understand every method to find and choose the best t-shirt printing method which fits best for you and fulfills your needs.

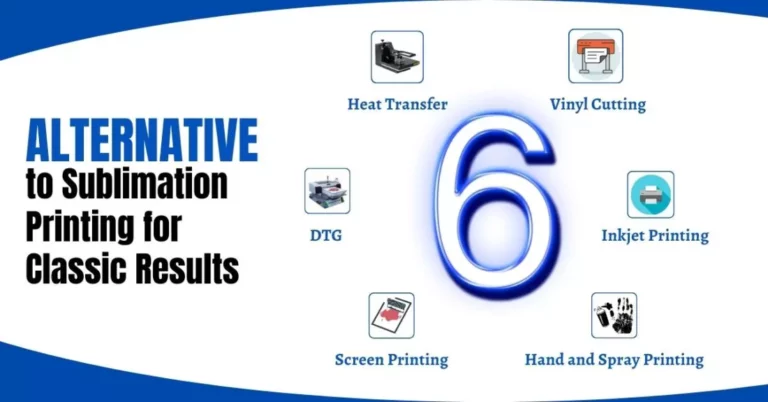

There are many ways to do Printing on the shirt, but today we will explain everything you need to know about Top 4 ways for T-shirt Printing and the complete method of each one. Those four ways are,

- Sublimation Printing

- Heat Transfer Printing

- Direct to Garment (DTG)

- Screen Printing

Sublimation Printing for T-shirts

Sublimation shirt printing, the process of printing that gives one of the most long-lasting prints on the substrate or specifically t-shirts. In addition, you can print any kind of color scheme with no limits on the shirts with sublimation.

The process of sublimating the shirt is relatively simple but before that, you need to make sure of some essential aspects. Otherwise, you will not able to achieve the results which you should have.

- Printer and Ink Quality

- Shirt Quality and Material

- Shirt Colour

- Temperature and Time

Printer and Ink Quality:

Printing the print is the first need of sublimation, you don’t want your color blended into each other, it can make your print quality poor. So always make sure that your printer is best for sublimation and can give the best results, for that you can check our review about the top 12 best sublimation printers to get a clear & better idea about sublimation printers.

After the printer, ink is something you can not neglect. You must have used original ink before printing your artwork because sometimes the actual color of the ink changes when it is heat pressed, so the best is to use genuine & authentic ink. If you are not sure about the inks, then you can read our top 8 best inks for sublimation printing.

Shirt Quality and Material:

While sublimating, the substrate should be polyester. If not 100% polyester then at least 60% plus it should be. The reason behind this is that in sublimation the ink infuses within the fabric. Although you can still use other materials can also be used for sublimation printing but no other fabric is familiar and suitable for it than polyester, The print will not be permanent, and most importantly the color and detailing of the print will be atrocious.

Shirt Color:

The color of the shirt is in the area of sublimation printing where you need to be very conscious. The best and simple practice for choosing the color of the t-shirt is to choose white or light colors. Because only on the white or light colors you can see the print clearly and it also looks classy. Whereas sublimation printing can’t print white colour.

Temperature and Time:

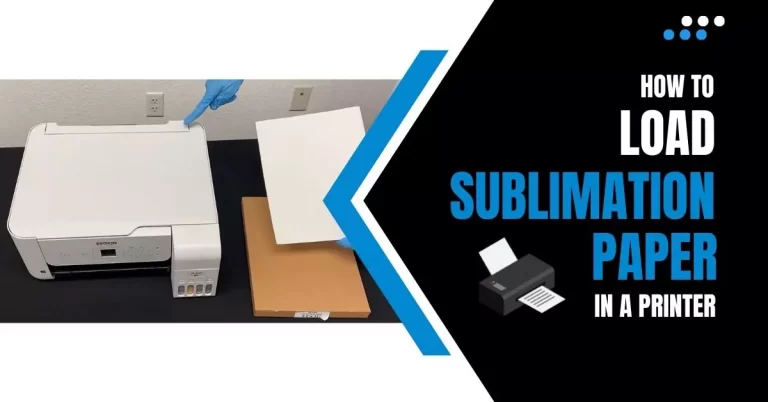

Once you are done with printing the print on the sublimation paper to prepare the shirt for it. Now it’s time to heat press the print on the shirt(substrate).

The ideal temperature for heat pressing is 370F-400F and about 60-100 seconds are enough. It also depends on which heat press you are using.

Heat Transfer Printing – T-shirt Printing Method

Heat transfer printing method is the type of printing method the results of which that can be achieved by most of the printers. But what makes it better is the variety of its printing different shapes. You can print the cap, mugs, t-shirts, or anything.

- You first need to print your design on the transparent sheet. Now mary the design onto the adhesive sheet to create your final transfer sheet.

- Marrying is the 2 step procedure in which you put your design on sheet “A” from sheet “B” to transfer on your shirt.

- The next step is to heat transfer the design onto the substrate using the heat press. Now peel the sheet away from the substrate i.e. shirts or mugs. Now put another sheet onto the design and use heat press again on that, by this you can cure the design onto the substrate and the design will stick onto the substrate longer than before.

- In terms of feel and durability, you will get decent results. You can feel the print on top of the shirt as it’s printed as another layer, not infusing or blending into the fabric directly. It can bear around 50 washes which is again a decent number.

- You are not limited to any material or shape in heat transfer. You can heat press the mugs, caps, t-shirts, etc. Because luckily in the market there is a large variety of shapes of heat press machines

- You can do heat transfer printing on a variety of different materials like polyester, cotton, or dark and light surfaces as well. Heat transfer printing can be quite conducive for small one-off orders because of the fact that you can switch designs between runs.

Direct to Garment OR DTG – T-shirt Printing Method

DTG or Direct to Garment printing is the process of printing in which you print your design directly on your substrate(shirt). It is more limited as compared to other methods because you can perform this only on a flat surface. But it can be done very quickly which can save much of your time.

- The process of DTG is a bit different, you first need to treat your shirt with a pre-treatment liquid. This liquid is kind of a liquid that needs to be sprayed on the substrate before printing, so the DTG ink can be able to bond with the substrate.

- After coating and spraying the garment with dtg liquid, you now need to insert it into the DTG machine and load the design. So the DTG machine can start printing the design on the garment. After inserting and loading this DTG machine world take around 30-40 seconds for a white shirt, and on the other hand, it can take 1-2 minutes for black shirts.

- After the design has finished printing, you can go ahead and put the shirt under the heat press to cure the layout and ink more permanently. This printing method is getting very popular now, even though it is very new as compared to the other methods in the market.

- You can use this printing method on light as well as on dark surfaces. You can even use the DTG method on polyester or cotton substrates but it needs to be flat because DTG printing can only be done on a flat surface.

- You can use this method for full-colour vibrant designs printing on a shirt and on the bulk orders it can be economical and beneficial at the same time.

- The DTG printing method is more streamlined and conducive in terms of printing in bulk quantity. You simply can queue up a bunch of orders in software and it can do the rest of the things. It’s also the better option in terms of time-saving, it can relatively print one print in 30-40 seconds on a white or light color t-shirt.

Screen Printing – T-shirt Printing Method

The process of printing with the help of ink and a mesh screen is called screen printing. It’s a good method of printing if you want to do the same print many times. But you need different screens for every color because one screen can be used for one colour at a time.

The process of screen printing is also very easy and simple to do. You just need a frame, mesh(better if it’s made up of silk), ink, squeegee, and some lights. If you did the screen printing in the right direction, you can achieve classic results on your shirts while printing. It’s not limited to any material, you can use it on wood, metal, polyester, or cotton.

- The process includes a few simple steps, first, you need to prepare the design you want to print and print it on transparent acetate film in black and white colour. Now prepare the screen by stretching the silk mesh over a frame(you can use nylon or polyester as well).

- Now apply the photo emulsion on both sides of the screen in a dark room and let it dry for 40-45 minutes. Photo emulsion is a liquid that undergoes the process and reaction which made it harder when exposed to UV or sunlight.

- Once the screen is dry, place the print on it and put a simple glass on it so it can’t slide around or move. Now expose the screen to UV light or sunlight. Once the process of hardening of photo emulsion is completed you can simply wash away the screen and the area exposed to UV light or sunlight will not wash away while the unexposed area will still be soft, and it will wash away.

- Now everything is ready, it’s time to print. Place the fabric on any flat surface and put the screen on top of it where you want that print. Now put some ink on the top of the screen and with the help of the squeegee drag the ink on the whole screen 1-2 times and your print is ready

- You can use the same screen for as many substrates as you want. If you want to add another colour, simply repeat the process and add another color of the ink and print it.

BONUS TIP: Put a good amount of pressure with a squeegee on the screen while dragging the ink on the whole area. Use rulers and tape to identify the exact area of the shirt where you want the print on.