Sublimation vs Heat Transfer: Which One Is Right for You

In the fascinating world of apparel decoration and customization, you’ve frequently heard the name of both sublimation and heat transfer. But if you are roaming, which one is better to choose between sublimation vs heat transfer for your business? Then, stop overthinking!!! We got you covered.

Today, in this article, I am going to compare both techniques in detail including their main differences, equipment required & procedure for the process, and pros and cons, to clear all the confusion for your effective decision making. Let’s get started…

A Quick Intro: What Is Sublimation vs Heat Transfer?

Sublimation is the technique that requires you to print an image or design on a special paper known as sublimation paper, then use heat to apply it to a substrate. In the process of sublimation, dye-based ink is used, which turns from solid to gas directly. When the ink is heated it fully disintegrates into the fabric. As sublimation is essentially a dye process, it produces the best results when the fabrics are either white or light-colored. Unlike other printing methods, it lasts longer, and will not crack or peel over time.

Recommended to read: Screen Printing vs Sublimation

Besides apparel decoration, sublimation is also commonly used for signs and banners, novelty items such as cell phone covers, plaques, coffee mugs, and other items with sublimation-friendly surfaces. See the image given below.

On the other hand, Heat Transfer is a process of decorating or customizing t-shirts, garments, or other items such as mugs, plates, tiles, mouse pads, ceramics, metals, glass, and even wood. Heat transfer produces high-quality, photo-realistic, and colorful images when executed in the right way. Like sublimation, heat transfer paper used in this process permanently transfers the image/text to your substrate when heat is pressed with sufficient time, temperature, and pressure.

Heat transfer papers are of two types, Inkjet and laser. Both papers require different types of printers which means laser transfer paper cannot be used with inkjet printers and vice versa. But mostly both papers are compatible with office printers/all-in-one printers. Heat transfer printing can be done on both colored and dark garments. Here’s a link to watch a youtube video, which will help you a lot in making a clear choice between heat transfer and sublimation.

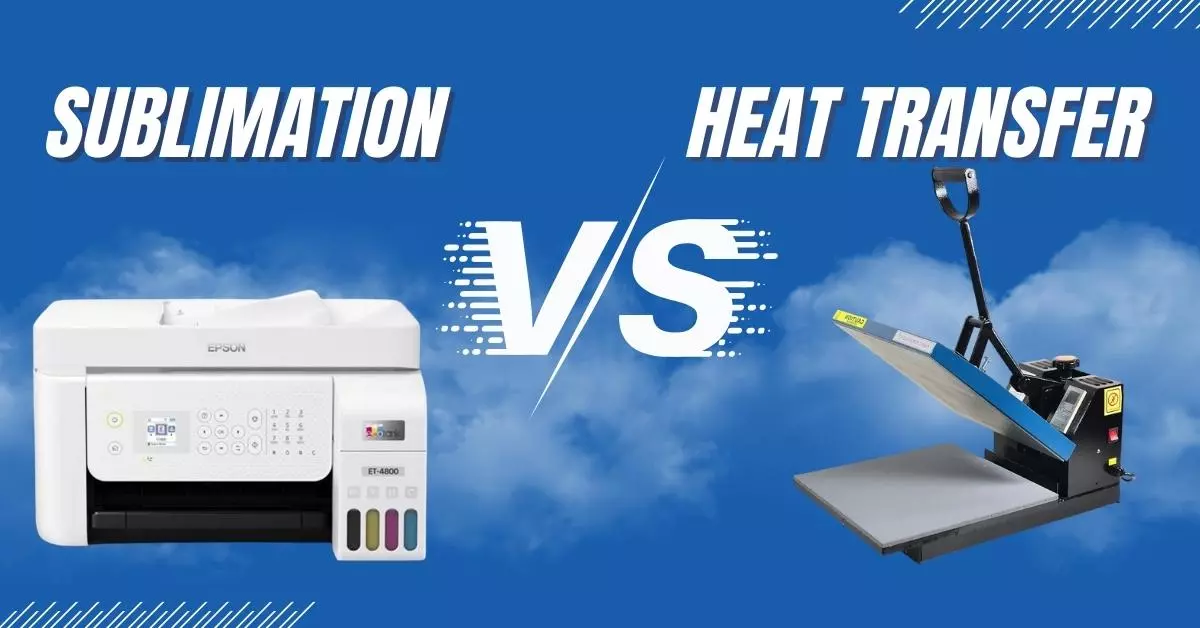

Sublimation vs Heat Transfer Main Differences

Except for the science behind the process of both techniques, they seem quite similar. But NO, there are many main differences between sublimation and heat transfer. These differences will surely help you in effective decision-making of whether sublimation is better or heat transfer. See the image given below.

Fabric Color:

The main difference between the sublimation and heat transfer is the color of the fabric onto which you can transfer the design. In sublimation, you can only print on white or light-colored items. Since it’s a dye-based process which means with help of heat ink penetrates into the fabric. So, you cannot transfer the design to dark-colored garments, as they will not be visible.

Alternatively, with heat transfer, there’s no limit on fabric color. Simply you can transfer the design on any substrate you want to, either light or dark colored. See the image given below.

Substrate and Fabric Type:

For sublimation, you cannot work with fabrics other than polyester. Even for harder surfaces you cannot just go to the store and grab a mug or other substrate and sublimate on it. Because sublimation only gives results on polyester, the other substrates like mugs, cell phone covers, laques, novelty gifts, etc used for sublimation must have a polymer coating that allows heat to disintegrate the dyes into the fabric.

The heat transfer technique of printing can be virtually used on any type of substrate and fabric such as polyester, cotton, blends, nylon, and more. You can decorate hard surfaces both with or without polymer coating. In a nutshell, heat transfer wins the point due to its property of being worked on any type of substrate and fabric.

Touch/Feel to the Hand and Durability:

In the process of sublimation, dye-based ink is used, which fully disintegrates into the fabric when heat and specific pressure are applied. This means, that when you touch the design it feels extremely soft. Moreover, sublimated prints are very durable and last long. If you take proper wash care of such fabrics, sublimated prints will not crack even after many years of use.

On the contrary, heat transfer designs stay on top of the fabric/substrate. The “touch/feel to the hand” of such design majorly depends upon the type of heat transfer paper being used in the process. The higher the quality of the transfer paper is, the smoother the design will be. Additionally, before you start noticing fading or cracking in the design, they become washed about 25 to 30 times before. So, they are not durable as sublimated designs but you can extend their washability and durability to a larger extent by using RIP software to rasterize your design.

Availability of Colors:

Sublimation can produce realistic coloration designs/images with high resolution and clarity. Full-color fabric decoration is possible through sublimation, which is especially beneficial when your customers require a specific color (for example, a specific color for their company logo) or if you want to print high-quality photos on your fabric decoration/soft substrate.

But with heat transfer printing, it is feasible that it will not produce the exact high resolution and photo-quality transfer, regardless of the type of heat transfer paper you use, either inkjet or laser. According to industry standards, light-colored textiles produced with inkjet or laser heat transfer paper get published with an OKI white toner laser printer, to achieve photo-quality prints with heat transfer printing.

Weeding:

In sublimation, no cutting or weeding of design is involved. Since only the areas of the sublimation paper that have sublimation ink on them are fully sublimated onto the garment or substrate when heat is applied. So, there’s no weeding or cutting involved in this technique of decorating apparel. In the case of heat transfer, you may need to “weed” or cut and trim your design before transferring it onto your fabric/substrate, depending on the type of heat transfer paper that you use. However, there are some self-weeding options for laser heat transfer paper – that eliminate the need of trimming away the background, but there are no inkjet self-weeding transfer papers available on the market. See the image given below.

Equipment Required and Start-up Cost:

Sublimation printing has a higher initial start-up cost though this cost has decreased significantly in recent years. Still, it requires more equipment than heat transfer printing. Its equipment includes a sublimation printer, dye or ink for the printer, paper for printing on the article, software for the printer, a heat press for printing, and the substrate/apparel for printing. But, no doubt, sublimation justifies the cost by providing longer washability and durability of the design.

On the other hand, the heat transfer printing technique is now one of the most cost-effective methods of apparel customization/decoration available today in the market, as it requires less equipment than sublimation. All you require is a laser or inkjet printer, heat transfer paper, a heat press, and the garments or substrate you wanted to decorate. So, once you have this equipment in your hand, you can print a beautiful gift for your family, close friends, or clients of your business.

Sublimation vs Heat Transfer Procedure

After, you’ve got an idea about the main differences between sublimation and heat transfer. Now, let’s dig deeper into the procedure of both techniques to know how they worked and how they are different from each other.

Procedure for Sublimation:

Sublimation is also referred to as dye-sublimation, it involves the disintegration of dye/ink into the substrate and a solid matter turns directly into a gas matter without transforming into a liquid matter.

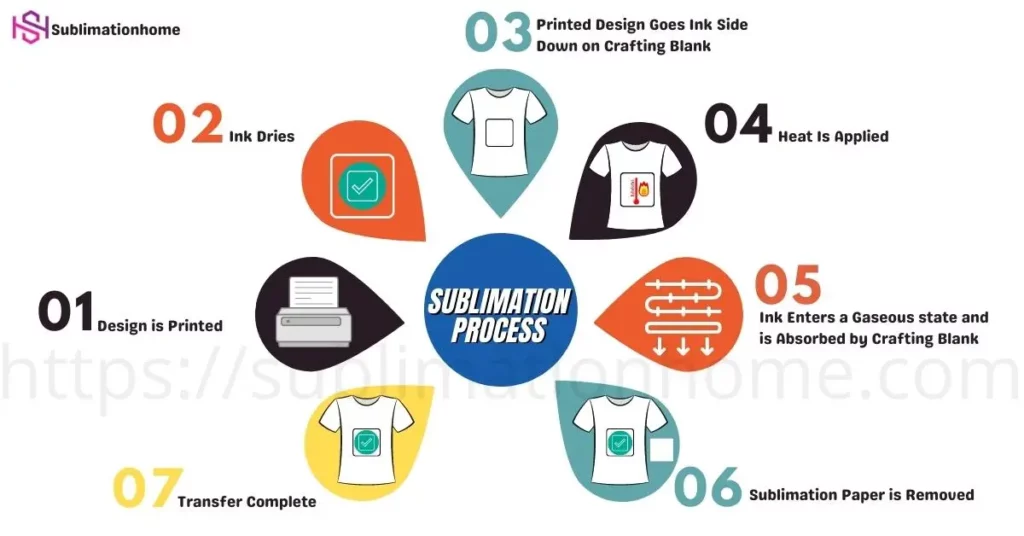

The basic procedure of sublimation printing includes the following steps:

- Edit and finalize the design you wanted to sublimate on the fabric/substrate.

- Using a sublimation printer, print the design on sublimation or heat transfer paper.

- Now, fix the design on the substrate and place heat-resistant tape or parchment paper above it. This will avoid the direct contact of heat with the design.

- Preheat the heat press at the recommended temperature given by the manual user.

- Run the product through a heat press. This will transfer the design from the paper to the substrate which means the dye will be fully integrated into the fabric/substrate. See the image given below.

Recommended to read: Sublimation Printing and How Does It Work

Procedure for Heat Transfer:

The procedure of heat transfer printing is quite different from sublimation, yet the steps are understandable and easy to follow.

The basic procedure of sublimation printing includes the following steps:

- First, the design will be printed onto a special transfer paper of high quality, which can imprint designs and images with clarity.

- The fabric/substrate is loaded into the heat press for pre-pressing, it stretches the fabric, allowing the inks to adhere to the fabric more easily.

- Then transfer the paper onto which the design is printed, and will be placed at the specific area of the substrate where you want the image to be printed.

- Place a parchment paper / resistant tape on the design to secure it firmly in place. This will also avoid blow-out – which happens due to direct contact between design and heat press.

- The heat press will hold the transfer paper and the garment together. During the heat pressing, the waxy ink melts and transfers to the garment properly.

- After about 15 seconds, the fabric is released from the heat press and set aside to cool down.

- Once everything has cooled down, remove the transfer paper from the substrate, and you will be left with an amazing, full-colored design. See the image given below.

Pros of Sublimation

It creates more high-quality and realistic designs on the substrate, upon transferring.

Sublimated designs are brighter, long-lasting, and far more resistant to cracking or fading.

The procedure is really easy to learn.

Pros of Heat Transfer

More affordable than sublimation, when it comes to the initial cost and equipment required.

Unlike sublimation, it can be done on any type of fabric like cotton, polyester, nylon, and many more.

It can be done on dark-colored fabric/substrates and the procedure is easy to learn for beginners.

Cons of Sublimation

Sublimation printing is limited to substrates or fabrics that contain a certain percentage of polymer.

When it comes to the initial cost of equipment and setup, it is more expensive than HTV printing.

No sublimation can be done properly on dark-colored substrates/garments.

Cons of Heat Transfer

It develops designs that stay on top of the garment, so are more prone to peeling or cracking.

Can handle designs with solid color blocks only; it is unable to accurately transfer sophisticated graphic designs.

Consider the relatively long time process, if you’re looking to tackle a large project.

Conclusion:

If your business needs basically focused on white and light-color polyester apparel and you want to produce the lightest hand and great durability and washability designs then Sublimation is a great option to opt for. Whereas, if you want to print on a wide range of materials with different color options, then Heat Transfer will be your best bet. In short, both techniques are famous printing techniques in the world of decorating apparel. But for the longer run, Sublimation will win the race. Ultimately, which one is the best for your business, depends majorly on the needs of your business and your customers.