Complete Sublimation Ceramic Blank Tile Printing Guide and Steps

Sublimating the ceramic blank tile is a fun process. You can make beautiful things and save your amazing moments on them. It is also a great gift idea to your loved ones, newly married couples, or your family members.

In addition to that, you can make money from tile sublimation printing by selling them. The process is easy to do and equipment that is being used for blank tile sublimation printing can also be used for regular printing. So you can get 2 in 1 advantage.

The process of sublimating a blank ceramic tile has a few simple steps. But before that, you need some required equipment that will be used for printing the ceramic blank tile.

Sublimation Tile Printing Needed Materials are,

1. Sublimation Printer: The sublimation printer is required to print the design on paper which you want to transfer on the ceramic tile.

NOTE: Your sublimation ink should be original or from the company recommended by your printers company. Only then you will have the best and vibrant colors print.

2. Heat Press Machine: A heat press machine is used to transfer print from paper to substrate-like ceramic tile. There are multiple types of heat press machines, for sublimation tile printing you can use any standard heat press machine.

3. Sublimation Paper: Sublimation paper is recommended to use instead of using a normal sheet. It has an additional step called “Marrying” that’s why it’s not recommended. With sublimation paper, you can print directly on it and use it directly on the ceramic tile to transfer the print without any additional step.

4. Heat Resisting Tape and Non-Stick Sheet: After placing the tile on the printed paper, tape the corners with heat-resisting tape. It protects the tile from shaking or moving.

A nonstick sheet might look useless but it’s very important to use as a precaution. While heat pressing the tile, you have to place it above the title and below the printed sublimation paper to protect the heat press machine from any unwanted ink.

The paper should be smooth, rough paper can transfer its roughness to the image and not leave the image as crisp and clear as it should be.

5. Gloves: Once heat pressing is done, the ceramic tile will be hot and you can’t touch your hand directly to it. So you have to use gloves to hold it. You can use any gloves, there is no specific recommendation for this.

6. Soft Fusion Pillow OR Heat Press Pillow: The soft fusion or heat press pillow is made up of cushioned bounce-back foam. Which has a feature to come to its original shape after heat press is done. It comes wrapped in a nonstick heat-resisting sheet.

This heat press pillow is used to protect the ceramic tile from cracking while heat pressing.

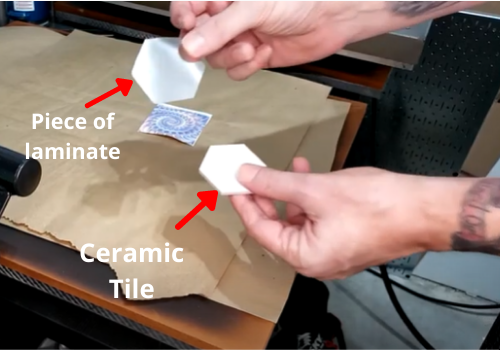

7. Ceramic Tile and Laminate Sheet: The most important and obvious requirement for sublimation tile printing. You can use any size of tile such as 6X6 or 6X8. Just make to print the size according to your tile size or half-inch extra so you have enough room to adjust the tile on paper.

A laminate sheet is needed for ceramic tile. The laminate sheet will be heat pressed to the ceramic tile first, after pressing them together laminate sheet will stick to the tile and now you can sublimate on the ceramic tile.

Process Guide Of Sublimation Tile Printing

The process of sublimation tile printing involves a few steps. You can get the best results by following these step by steps.

Step 1:

Make your print-ready. Make sure to print the size according to the size of your tile. Alongside, prepare other accessories ready and preheat the heat press machine on 375-400 F for 3-4 minutes.

The time and temperature also depend on what tile and heat press machine you are using. So adjust accordingly.

Step 2:

Apply laminate coating to the ceramic tile. Cut the laminate sheet according to the size of the tile. Leave half-inch extra because when the laminate is heated, it gets shrunk. Place the heat press cushion on the heat press, place the laminate sheet on it and place your tile on top of the laminate sheet.

Now put a nonstick sheet above the tiles and heat press them for 90 seconds at 375-400 F with low to medium pressure

TIP: Make sure that the rough side is against the ceramic. It helps to stick it really well and give a nice smooth finish.

Step 3:

Once the laminate sheet is pressed on the ceramic tile, now its time to sublimate it with actual print. Place the sublimated paper on the heat press on the same heat press pillow. Above the paper, place the ceramic tile according to the design. Tape the corners of the tile with sublimation paper.

Taping the corner protects the tile from shaking while pressing.

Step 4:

Heat press the tile at 375-400 F for 90-120 seconds. Time also varies on how larger tile you are sublimating so adjust accordingly by adding extra seconds to pressing.

Once the heat press is done, wear your gloves and remove the nonstick sheet and tile from the paper. Wearing gloves is a must because tile will be very hot and it may burn your hand if you directly hold it.

Step 5:

Your tile sublimation printing is done. In case if your tile has any extra laminate sheet on its ends, cut it with the Exacto knife for perfect edges.

If you follow these steps correctly, you will easily achieve excellent and crisp sublimation results on your tile after sublimating it.

DO’S and DON’TS

Pros

Always wipe your piece of tile to remove any extra dirt or humidity before pressing it with a laminate sheet.

Make sure to use heat gloves while holding the tile after heat pressing it.

Must use a nonstick sheet above the tile to protect your heat press from any unwanted ink.

Cons

Do not use high pressure while heat pressing. Use low-medium pressure. High pressure can damage and crack your tile.

TIP: If you want to protect the back of your ceramic tile, you can use self-adhesive cork sticker paper on it. Do it once the tile is sublimated and cooled down.

Conclusion

Sublimation printing on ceramic tile is possible. You just need to have the right equipment and knowledge of how to do that. In addition, using high-quality material will also help you to achieve great and crisp results. You can use these sublimated ceramic tiles as a gift to your loved ones. As well as sell them to make some good money.