Phone Cases Sublimation Printing – How To Do and Complete Guide

Have you noticed we carry mobile phones with us everywhere we go… Having a unique and personalized case is a great way to show off your personality, interests, or advocacies in public. Now, the question arises, how can you make a unique and personalized phone case? The answer is: “Sublimation”. Yes, you’ve heard right. Sublimation is the gateway for creating phone cases with unique, personalized designs of your choice.

Moreover, a sublimated phone case can be a great gift for your close friends and family. You can earn by selling them too, which means creating solicit meaningful photos for your clients. So, today, in this topic we’ll explore all the equipment that you’ll be required for creating sublimated phone cases. After, we will learn the steps of doing sublimation on phone cases.

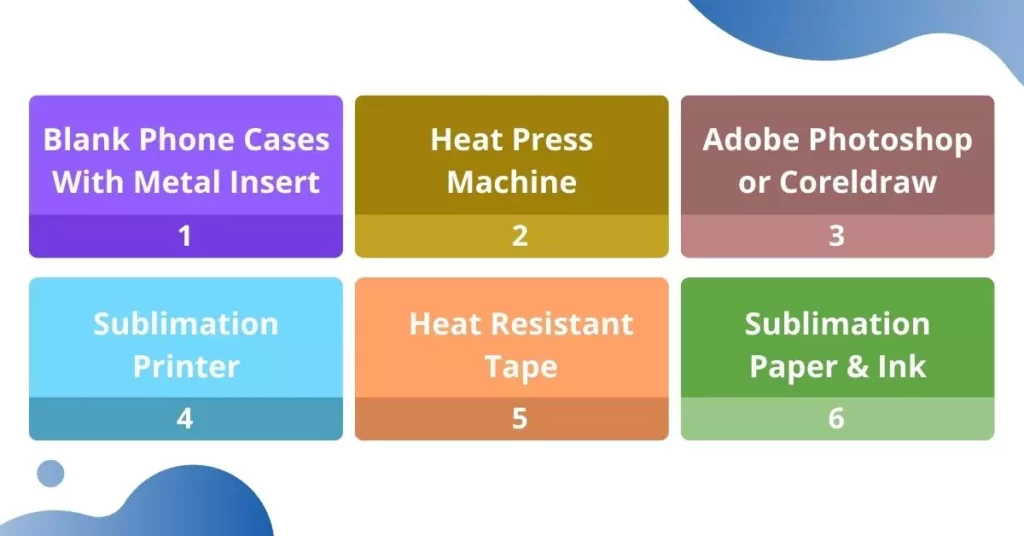

Required Material: What Do You Need to Sublimate on a Phone Case?

Here’s the list of items you will be required for sublimating design of your own choice on a Phone case for weather yourself or for your small business. Only, investing in the right equipment will give you desirable results, so you have to be precise while investing in the equipment. Let’s get into it.

1. Blank Phone Cases With Metal Insert

The very first thing is to buy a blank phone case that is compatible with you/your client’s mobile model. On the metal insert, you’ll sublimate or “heat-transfer” the design then stick it to the mobile casing. You can find a wide range of blank phone cases in the market. Below, I am giving links to a few mobile cases for sublimation printing. They all can be used essentially the same way, which I’ll describe in the section “How to do sublimation printing on a Phone Case?”.

- Innosub Sublimation Phone Cases Compatible with iPhone 11

- Innosub Sublimation Phone Cases Compatible with iPhone XR

- 75 x Apple iPhone X-Rubber-Black – Blank dye case + Inserts for dye Sublimation

- Sublimation Blanks Phone Case Covers for iPhone XR 6.1-Protective Shockproof Slim Case

- Sublimation Blank Phone Case Blanks Cover for Samsung Galaxy S8 – Protective Shockproof Slim Case & Anti-Slip

2. Heat Press Machine

For sublimating design on metal inserts, the substrate that comes with blank mobile cases, you’ll need a heat press machine. Make sure you invest in high-quality heating from a reputable company. You can easily buy them online through Amazon or their official websites. But who doesn’t want to avail amazing discounts from Amazon? Here are some high-quality heat press machines that work well for aluminum insert sheets of mobile cases.

IMPORTANT: If you want to buy a different heat press instead of our recommended one, ensure you choose one with an extensive range of temperature settings, so they can meet the heating needs of different covers for phone cases.

F2c Pro Heat Press 12×15 Inch Combo 5 in 1 Heat Press Machine: Top Pick

There’s a range of heat presses available in the market. But this F2C Pro Heat Press has really reduced the risk and confusion of choice as it’s highly cost-effective and ensures the premium quality of work, so don’t hesitate to invest in it.

| Brand | F2C |

| Material | Vinyl, Silicone |

| Color | Balck |

| Dimensions | 20.6 x 19.3 x 20.2 inches |

| Item weight | 45.8 pounds |

| Time control | 0-999 seconds |

| Temperature range | 200-450 °F(95-232 °C) |

| Power | 1100 Walts |

| Warranty | 2 years |

These are the features of F2c Pro Heat Press 12×15 Inch Combo 5 in 1 Heat Press Machine.

Premium Quality: Its 12 x 15 inches (38 x 30 cm) large heat plate provides a large surface to transfer design/pattern onto your aimed items. It is of perfect size for an at-home crafter. The platen is covered by a Teflon coating which prevents scorching of transfers. Its thickened bottom silicone pad and sponge pad not only protect your vinyl or sublimation but also help the cloth/surface become flattered to make a great print effect.

360 Degree Rotation & Full Range Pressure: The swing arm of the heat press is fully rotatable at 360 degrees and the slide-out tray is designed on the bottom, which allows the heating element to move safely to the side and effectively reduces the chance of accidental contact.

The full range of pressure adjustment knobs allows you to set the desired pressure according to the thickness of the various materials you’re using for sublimation.

Upgrade Dual Display: With its upgraded digital control box you can easily set the desired time and temperature (℉ and ℃ alternative) according to different materials. When the preset temperature reaches it stops heating and a sound alarm will be issued on-time completion. The overload protector button pop-up when the voltage is unstable or too high, so it can protect the control box as well as the heat plate.

Note: Before using the heat press, it’s recommended to pre-heat it for about 15 minutes, so it gets heated evenly. For more instructions, you can read the user manual.

Tusy Heat Press Machine: Easy-To-Use

In the field of heat transfer vinyl, tusy heat press machines allow their users to get a better sublimation experience.

| Brand | TUSY |

| Material | Vinyl |

| Color | Balck |

| Dimensions | 30 x 19 x 17 inches |

| Item weight | 46.1 pounds |

| Time control | 0-999 seconds |

| Temperature range | 32-482°F (0 – 250 ℃) |

| Power | 1400 Walts |

These are the features of Tusy Heat Press Machine.

Easy to use: The unique handheld design of this heat press makes it easy to use and ensures higher accuracy & more convenience than a 360 degrees swing away heat press.

LCD Control Board: The LCD control board displays the temperature (in Fahrenheit) and time, making it efficient to use without any guesswork. You can also set the precise time and temperature on it according to the type of material you’re sublimating onto.

Overheating Protection: Its overheating protection makes it much safer to use. When the temperature goes too high, the breaker will automatically shut the machine off. Thus avoid any accidents like burning, fire, etc.

Fancierstudio Heat Press: Best on Budget

Fancierstudio Heat press works great for sublimating phone cases. It is very ideal for small businesses as many people found it budget-friendly. It includes a sheet and coating on the heat plate. The silicon rubber base of this heat press is slightly glued down for easy replacement. Its compact and upward-opening model saves space a lot. It can go with so many materials for applying transfers such as letters, numbers, and images on t-shirts, garments, bags, mouse mats, jigsaw puzzles, ID badges, ceramic tiles, aluminum flat sheets, and other items. See the image given below.

| Brand | Fancierstudio |

| Material | Steel frame aluminum heat platen |

| Color | Blue balck |

| Dimensions | 30 x 19 x 17 inches |

| Item weight | 43 pounds |

| Time control | 0-999 seconds |

| Temperature range | 0-699 °F |

| Power | 1400 Walts |

3. Design Software Like Adobe Photoshop or Coreldraw

Most professional sublimation printers come with specific programs that are required to get installed for printing the designs. This is known as RIP software. Whereas, other sublimation printers can be used with designing software of your own choice.

For the actual designs & editing, you need access to any design software like Adobe Photoshop or Corel Draw. Then selected design gets transferred into the required software for printing.

Note: If you’re running your sublimation business then it’s suggested to ask your client for design if they want unique and highly personalized phone cases.

4. Sublimation Printer: For Printing Your Cover’s Design

For sublimating your desired design on a phone case, you have to print it first on sublimation paper. Sublimation printers are different from normal printers. Sublimation printers use special ink that will sublimate into your substrate when you use a heat press and they have high resolution for significant results. But, now with the help of conversion kits, you can convert your modern photo printers into the best sublimation printers too.

Sawgrass SG500 and Sawgrass Virtuoso SG1000 are specifically designed for sublimation printing. So, they are the best options to opt for.

Link for Products to Buy:

5. Heat Resistant Tape

The protection provided by parchment paper against heat transfer isn’t enough at all. You need heat-resistant tape for this purpose. Place it between the sublimation paper and metal insert so the heating element of the heat press never comes into direct contact with the surface. It also holds the insert metal sheet in place when the heat press transfers the ink. It also saves your design from blowing out, which may happen due to over-heat / over-pressure applied during heat transfer.

6. Sublimation Paper & Ink

Modern phone cases are made of 2 pieces, a rubber/plastic phone case with an inserted metal (aluminum) flat substrate. So, you have to go for good quality sublimation paper for desired results.

Sublimation inks provide the most effective results when they are being used with their compatible printer. Ensure you buy the correct printhead and ink thermoplastics for your printers. The sublimation paper you are using must reflect the exact color of the ink, so select the same type of paper as the ink.

How to Do Sublimation Printing on a Phone Case?

After discussing the required equipment, let’s have a look towards the step-by-step guide of doing sublimation printing on a phone case.

- First, print a mirror image of your required design on sublimation paper using a sublimation printer with its compatible sublimation ink.

- After printing your design, cut out the outline of the design. Ensure to leave 2-3 inches of the border of the design.

- Remove the protective film from the aluminum insert plate of the sublimation blank phone case.

- Now set the heat press on pre-heat, at the temperature recommended by the manufacturer of the phone case blank, typically 350°F to 400°F.

- Next, set the printed design over the uncovered white sublimation blank and secure it with help of heat-resistant tape.

- Into the pre-heated pressing machine, set the taped design and blank sandwich. In this step, you have to use protective layers on top and bottom. The protective layer can be a silicone sheet, parchment paper, butcher paper, or Teflon sheet; it will protect the design from coming into direct contact with the machine.

- Close the heat press and set a timer based on the control box. Time can vary by the manufacturer of the sublimation phone case, typically the heat pressing time is 80-120 seconds.

Here’s a link to a youtube video, to watch how to Sublimate on a Phone Case.

- During the heat pressing, apply a little amount of pressure while staying gentle.

- Once the time limit reaches its level, this will be the point when ink will sublimate from the paper onto the phone case.

- Now, remove the sandwich from the heat press and let it get cool enough so that you don’t burn your hand.

- Remove the paper to check whether the design has fully transferred to the aluminum substrate or not. If yes, then congratulations you’ve done the job successfully.

- For the next part, take the rubber/plastic blank case. Remove the protective film from its inner side, which exposes an adhesive site after.

- Put the shiny aluminum side (on which you’ve sublimated the design) down into the phone case. Use your fingers to press the aluminum case onto the adhesive back of the flexible phone case, so it adheres perfectly to it.

- Wow, the gorgeous sublimated phone case is now ready to show in mirror selfies.

Conclusion:

At the end of the day remember, making a sublimating phone case is not really that easy at first. Before you start, you have to gather and spend on the right equipment. But once you get the hang of it, by following the right steps that I’ve mentioned above, you can master sublimating a phone case in just a few tries. You can even sell them at a good price, as sublimated phone cases are one of the fastest growing trends in the world. So sublimate unique designs, sell it to your close friends, and see how well it goes!!.