Sublimation Printing On Cotton T-Shirts With Complete Guide and 7 FAQs

Sublimation printing on the cotton t-shirt is possible, even if the substrate is 100% cotton. You can still sublimate it and acquire the tremendous vibrant print results and infused ink into the substrate, which is made up of 100% cotton.

The process of sublimating any cotton shirt or apparel is simple and standard. But there is an extra layer in a procedure that enables the cotton to get sublimated. The life of the image on the substrate is also better and you can sublimate any cotton substrate like t-shirts, hoodies, shirts, or any cotton apparel.

Sublimation Printing On Cotton T-shirts – Requirements and Process

Sublimation on the cotton is very much the same as the normal sublimation process. The difference lies in the additional step of spraying a solution. This solution is known as Sublimation on cotton fluid OR Sublimation coating spray for cotton.

This fluid is used to pretreat the cotton shirt(substrate) for sublimation. What this fluid does is that it makes the area(where you sprayed it) sublimation friendly and once the area where your sprayed is dried, you can now sublimate there.

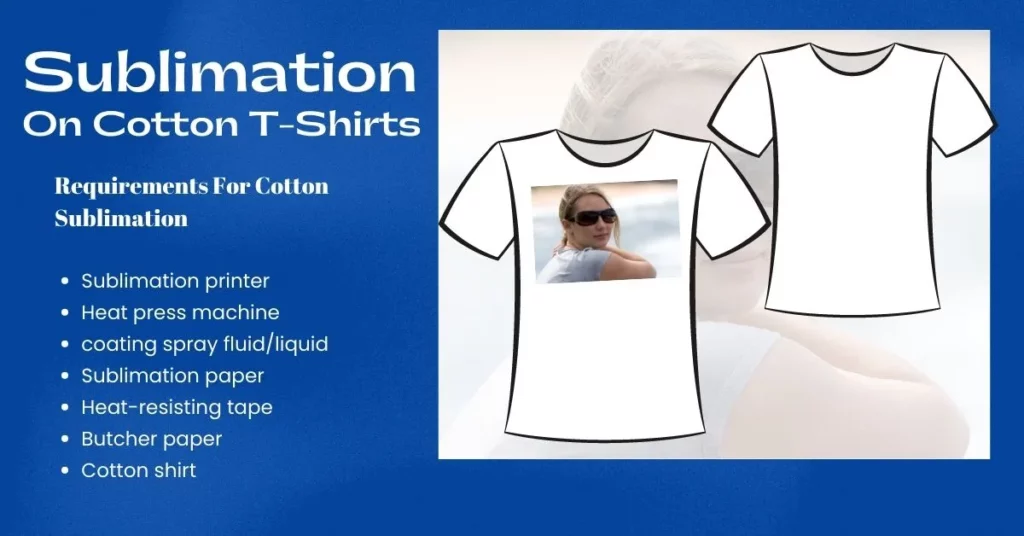

Requirements For Cotton Sublimation:

There are some equipment required for cotton sublimation,

- Sublimation printer: Used to print the image/design you want to sublimate on your cotton shirt

- Heat press machine: Sublimated image/design needs to be transferred on the shirt and it requires heat. Heat press machines are used to transfer the design to the substrate.

- Sublimation coating spray fluid/liquid: This liquid is used to pretreat the area on the cotton shirt where you want to do sublimation. This liquid makes the cotton sublimatable.

- Sublimation paper/sheet: Sublimation paper/sheet is used to get the design/image printed on.

- Heat-resisting tape: Heat-resisting tape is used to tape the sheet with the substrate while pressing it with a heat press.

- Butcher paper: To protect our backside and heat press from the sublimation ink, we use this butcher paper as a layer.

- Cotton shirt(Substrate): Cotton shirt is most important because it will be used as a substrate on which you will do sublimation.

Complete Process Of Cotton Sublimation:

The process of cotton sublimation consists of a few simple steps,

- The first step is to arrange all the equipment you needed for cotton shirt sublimation. Then get your print-ready on your laptop. Now print your design/image using a sublimation printer on sublimation paper.

- The second step is to get your cotton shirt ready. It’s recommended to use light color shirts for better results. Using a spray bottle, spray the area you want to sublimate with Sublimation Cotton Spray Liquid. Heat press the shirt for a few seconds after spraying to make it dry.

- The third step is to heat press your design on the cotton shirt. For that, you need to put the printed sublimation paper on the area where you sprayed the sublimation liquid. Insert the butcher paper sheet between the shirt and above the sublimation paper to protect the backside of the shirt and heat press machine from the ink.

- Heat press your cotton shirt using heat press with medium pressure, 375F – 400F for 120-140seconds( the time and temperature also depend on what printer are you using, so adjust it accordingly). Once your pressing is done, remove the butcher paper and sublimation sheet from the shirt, and your sublimated cotton shirt is ready.

Advantages and Disadvantages Of Cotton Sublimation

Advantages

Cotton sublimation opens a huge variety of substrates that can be sublimated.

Easy to do the process, and cotton shirts/apparel are very cheap and low in price.

Cotton sublimation also results in vibrant color prints.

You can sublimate any cotton substrate such as bags, t-shirts, hoodies, or many more.

Great business opportunity for professionals.

Disadvantages

Sublimation print on the cotton doesn’t last as long as it does on the polyester.

7 Tips For The Best Cotton Sublimation Results

There are few things that you learn only by doing the cotton sublimation yourself. But we can save your time by telling you those tips. Top 7 of those tips for the best sublimation results are,

Tip 1: Never wash the cotton sublimated shirt or any apparel before 12 hours of sublimating it. Always allow the print to get set and settle. You can wash it after 12 hours without any hesitation.

Tip 2: Make sure your heat press settings. Pressing more or less than required can make your sublimation print faded or blurry.

Tip 3: Must tape your corners of the sublimation paper when played on the shirt for pressing. This taping makes sure that your sheet does not shake or move away from the area you sprayed the sublimation coating liquid.

Tip 4: Always use a spray bottle for spraying sublimation coating liquid. Never lay the liquid directly on the shirt in bulk.

Tip 5: Make sure to heat press your t-shirt after spraying a sublimation coating liquid on it to make it dry for the actual sublimation process.

Tip 6: If your t-shirt is harder after heat pressing, don’t worry. Wash it once after 12 hours and it will be back to normal.

Tip 7: Must use the butcher paper or any other standard paper sheet and put it inside the shirt to protect the backside from the ink and above the sublimation sheet to protect heat press from the ink. The ink leakage happens very very rarely but taking care of this is better.

Conclusion

Sublimating cotton is a possible and exciting process. Not many people know that you can even sublimate on 100% cotton. It is a great business opportunity as well. Even though the results of cotton sublimation are great, and vibrant but still if we compare sublimation on cotton vs sublimation on polyester then polyester sublimation has a clearer edge. Because it is made t be sublimated while for cotton, we use sublimation liquid to make the area sublimatable where we want to sublimate.