How Does an Inkjet Printer Work?

Inkjet printers first appeared on the consumer market in the late 1980s, after being in development for more than twenty years. In the mid-1970s, printer companies recognized the potential of the technology that would obsolete dot matrix printers. So, the main challenge was to create an affordable inkjet printer that reliably produced high-quality printouts. There was no single inventor for the inkjet printers instead, a coalition of companies including Epson, HP, and Canon, led the charge of it.

Since their introduction in the latter half of the 1980s, Inkjet printers have grown in popularity and performance due to significant decrease in their prices. Today, wherever you’re working if you look around then there’s probably a high chance of having an inkjet printer nearby. There are two main reasons for the widespread adoption of ink jet printers:

- Low purchase price.

- Impressive image quality that exceeds that of dot-matrix printers.

If you want to learn how various parts of inkjet printers work together to create an image then continue reading…

What is an Inkjet Printer and How Does it Work?

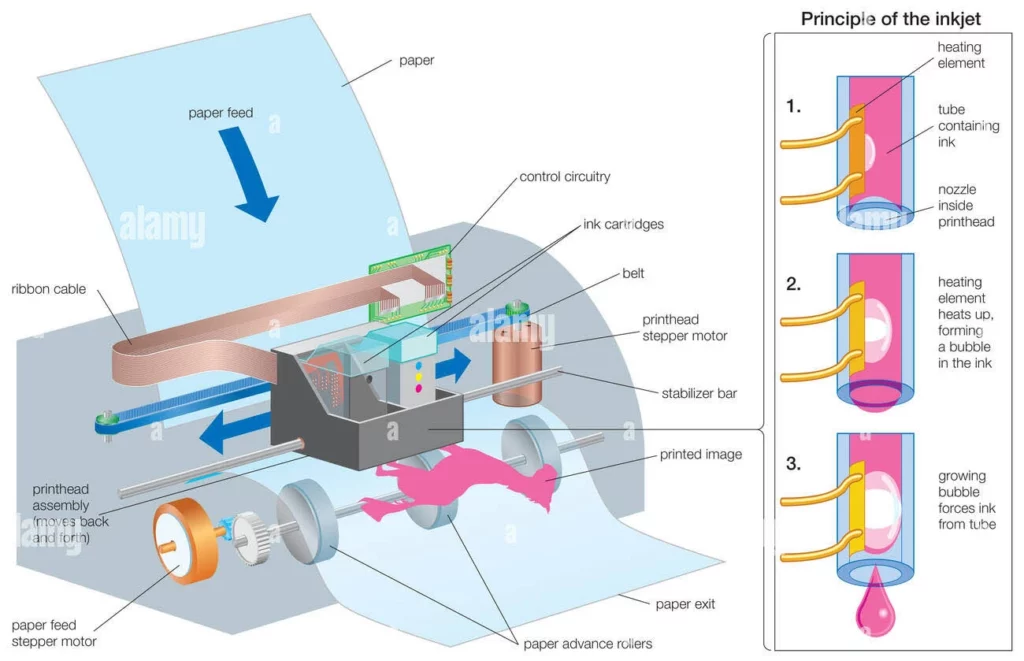

An inkjet printer is a computer peripheral that prints hard copies of text documents or photographs by spraying extremely small ink droplets directly onto the paper or sublimation paper. The ink dots sprayed by inkjet printers are usually between 50 and 60 microns in diameter, positioned very precisely with resolution of 1440×720 dots per inch(dpi) and can be of different colors combined together to create high-end quality images.

An average inkjet printer sprays 600 dots per inch (dpi) while an advanced inkjet printer sprays 5,000 dpi to make higher quality prints.

The working principle of inkjet printers is based on two different technologies used by printer manufacturing companies; one is thermal bubble and other is piezoelectric. The detailed explanation of both techniques is given below:

Thermal Bubble Heat:

Thermal bubble technique is commonly known as bubble jet and sublimation printer manufacturers such as Canon and HP (Hewlett Packard) used it. In a thermal inkjet printer, tiny resistors generate heat, which evaporates ink to create a bubble. As the bubble expands, some ink is pushed out of a nozzle onto the paper. Then the bubble “pops” (collapses) and a vacuum is created. This pulls more ink from the cartridge into the print head. A typical bubble jet print head contains 300 or 600 tiny nozzles, each of which can fire droplets simultaneously for printing an image or document. Watch out this interesting video by Lesics to know how an inkjet printer works.

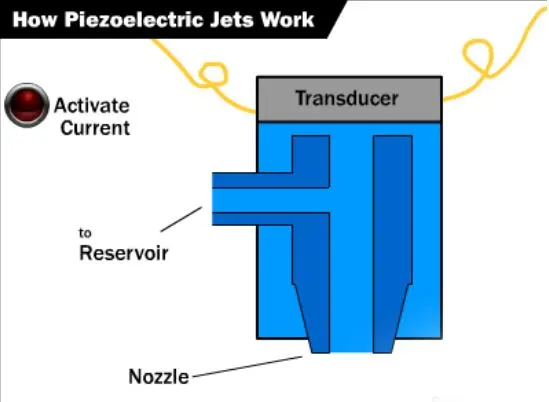

Piezoelectric – Vibration:

Epson first used this technique, and this technology uses piezo crystals. Every nozzle has a crystal installed on the back side of the ink reservoir. Crystal picks up the tiny electric charge and begins to vibrate. While the crystal vibrates inward, a small amount of ink is pushed out of the nozzle. When it starts vibrating outward, it draws more ink into the reservoir to replace the ink sprayed out. See the image given below, to know how piezoelectric technique of printing works.

Inkjet VS Thermal Printer – Which One Is Better

To know which one is better, here’s a detailed comparison between both printing techniques used by inkjet printers but you should check if your printer is inkjet. Thermal printheads are efficient and can provide high quality and speedy prints when compared to piezo-electric heads; however, unlike piezo, they only work with water-based inks and are typically confined to indoor applications only. Moreover, for high resolution image and art designs, the piezoelectric printing technique works better.

The thermal bubble technique uses heater resistors that are significantly smaller than piezoelectric elements. It does boil a thin layer of ink (approximately 1/1000th of the ink is boiled, vapourized, and re-condensed during operation). Because of the boiling, the ink must be designed to avoid the formation of thermal decomposition products in the ink channels. On the other hand, piezoelectric ink jets do not cause the ink to boil. However, in practice, ink jet printing inks have excellent performance for home and office inkjet printers and suffer no degradation under the boiling experienced in a thermal bubble inkjet printer.

Inshort, if you don’t want to put some extra care in the design of ink components and want some high-end images to print, then piezoelectric is good to go. Otherwise, ink boiling has not been a major minus in the performance of thermal bubble inkjet printing,

Printing Process of Inkjet Printer

After loading the paper feeder, when you click on the printing button then a number of steps are performed by the inkjet printer to process the printing.

- First, the data to be printed is sent to the printer driver by the software application you are using.

- Driver converts the data into a format that the printer understands and verifies that the printer is online and ready to print.

- Then the driver sends data from the computer to the printer via the connection interface (parallel port, USB, etc.).

- The data is sent to the printer from the computer. It keeps a set amount of data in a buffer. Depending on the model, the buffer size can range from 512 KB RAM to 16 MB RAM. Buffers allows the computer to complete the printing process quickly rather than waiting for the actual page to print. Buffers of larger sizes can easily hold complex documents or several basic documents.

- If the printer has not been used for a while, it will automatically perform a short clean cycle to ensure that the print head(s) are clean. Once the clean cycle is finished, the printer is ready to print.

- The paper feed stepper motor is activated by the control circuitry. This engages the rollers, which feed a sheet of paper into the printer from the paper tray/feeder. When there is paper in the tray or feeder, a small trigger mechanism in the tray/feeder is depressed. If the trigger is not depressed, the printer illuminates the “Out of Paper” LED and notifies the computer.

- The print head stepper motor uses the belt to move the print head assembly across the page after the paper is fed into the printer and positioned at the start of the page. When the print head sprays dots of ink on the page, the motor pauses for a fraction of a second then sprays dots of ink on the page and moves a tiny bit before stopping again. This step is so fast that it appears to be a continuous motion.

- At each stop, multiple dots are created. It precisely sprays the CMYK colors to create any other color imaginable.

- The paper feed stepper motor advances the paper a fraction of an inch, at the end of each complete pass. Depending on the inkjet model, the print head is either reset to the beginning of the page or simply reverses direction and begins to move back across the page as it prints.

- This procedure is repeated until the page is printed. The time it takes to print a page varies greatly between printers. It will also vary depending on the page’s complexity and the size of any images on the page. For instance, if you’re printing black text then an inkjet printer can print 16 pages per minute but this speed gets slower to print one, full-color, page-sized image.

- When the printing is finished, the print head is parked. The rollers are spun by the paper feed stepper motor to push the completed page into the output tray. Most printers nowadays use inks that dry quickly, allowing you to pick up the sheet without smudging it or waiting to let it dry for a while.

Components of Inkjet Printer & Their Functionality

Let’s figure out how various parts of an inkjet printer work together to create printouts of images or documents.

1. Print Head Assembly:

The printhead is a component of the printer that houses ink cartridges and actually sprays ink onto the paper. It is usually found under the printer’s cover and can become clogged with ink over time. Here’s the assembly of the printhead of an inkjet printer.

- Print head: The print head, the heart of an inkjet printer, contains a series of nozzles that spray ink drops.

- Ink cartridges: Depending on the printer’s manufacturer and model, ink cartridges come in a variety of combinations, which can include a separate black and color cartridge, a single color and black cartridge, or even a cartridge for each ink color. Some inkjet printer cartridges include the print head itself.

- Print head stepper motor: The print head assembly (print head and ink cartridges) is moved back and forth across the paper by a stepper motor. When the printer is not in use, another stepper motor parks the print head assembly. Parking prevents the print head assembly from moving accidentally, much like a parking brake on a car.

- Belt: A belt connects the print head assembly to the stepper motor.

- Stabilizer belt: A stabilizer bar is used in the print head assembly to ensure precise and controlled movements while printing. See the below image to understand visually.

2. Paper feed assembly

Paper feed is a function of the printer that allows an automatic insertion of paper through it for printing. The paper feed assembly of an inkjet printer involves:

- Paper tray/feeder: Most inkjet printers have a tray into which you load paper. Some printers dispense with the standard tray instead of a feeder. The feeder typically snaps open at an angle on the printer’s back, allowing you to insert paper into it. Feeders do not typically hold as much paper as a traditional paper tray. If you overload the paper tray / feeder, it’ll turn into a paper jam and you should read paper jam hacks.

- Rollers: A set of rollers pulls the paper in from the paper tray / feeder and passes the paper towards the print head, when its assembly is ready for another pass.

- Paper feed stepper motor: Feed paper stepper motor drives the rollers to move the paper in precise increments to ensure a continuous image is printed.

- Power supply: Earlier printers often had an external transformer, however, most of the printers sold today use a standard power supply that is already incorporated into the printer.

- Control circuitry: A small but sophisticated amount of circuitry is built inside the printer, that controls all mechanical aspects of operation as well as decodes information sent to the printer from the computer.

- Interface port: Many printers still use the parallel port, but most of the advanced printers use the USB port. A few printers use a serial port or a small computer system interface (SCSI) port for connecting purposes.

Beside having low initial cost, inkjet printers have so many other advantages that are the cause of their popularity for printing jobs in houses and offices. They use ink cartridges for highly pigmented & visible prints, unlike laser printers they don’t require any start up time, and are very portable due to their light weighted body and plug-and-play kind of device. In this article, we have completely described the whole printing process of inkjet printers. Hope you’ve understood the job now.

Recommended to read: Ink Tank vs. Ink Cartridge